Global trade turns on the hinge of sound logistics. If your company’s raw materials, goods, and finances arrive later than expected, the impact on the rest of your business processes can be disastrous.

You could disrupt your production schedules, your customers could get their orders late, or you could run out of stock.

You could also experience cash flow issues and increased supply chain costs due to alternative mitigating arrangements. The problems can mount up fast.

Supply chain optimization is paramount for businesses seeking efficiency and cost reduction. So, we’ve compiled some research-backed tips for improving logistical performance and minimizing hidden costs.

Importance of Supply Chain Optimization

According to a McKinsey survey, 93 percent of businesses intended to make their supply chains more flexible, agile, and resilient after the Covid pandemic.

But this was not simply a knee-jerk response to an emergency. All the pandemic did was reveal weaknesses in their processes.

And considering the many benefits of supply chain optimization, it’s easy to see why so many took the opportunity to do it.

- Enhanced inventory management: Optimized supply chains enable better inventory control. It reduces stockouts and excess inventory, which leads to minimized carrying costs.

- Better demand forecasting: Accurate demand forecasting enables optimized production and procurement. It, too, minimizes stockouts, reduces excess inventory, and improves operational efficiency while facilitating smart procurement strategies.

- Improved customer satisfaction: Optimizing the supply chain allows businesses to improve order fulfillment speed, accuracy, and reliability. This results in improved customer satisfaction and loyalty.

- Lower carbon footprint: By optimizing transportation routes, reducing packaging waste, and implementing sustainable practices, your small business can conserve resources and contribute to a greener, more sustainable future.

- Overall reduced costs: Supply chain optimization helps identify and eliminate unnecessary costs, such as excess inventory, inefficient transportation, and redundant processes. Addressing these will lead to significant cost savings.

Image sourced from McKinsey survey

How to Optimize the Supply Chain and Minimize Costs

So, what best practices can your company implement to guarantee a robust and reliable supply chain?

-

- Map our current supply chain processes.

- Identify bottlenecks and factors influencing costs.

- Forecast demand and align with production and producement.

- Review vendor and partnership performance.

- Streamline internal and external communication and collaboration.

- Implement inventory control and warehousing techniques.

- Leverage technology for real-time visibility and tracking.

- Optimize logistics and transportation efficiencies.

- Monitoring and consistently improving supply chain performance.

-

Map out current supply chain processes

The first step toward improvement is to evaluate your current business processes.

Start by mapping out and documenting each step in the materials, information, and finances flow. Analyze the activities, dependencies, and interactions among your suppliers, manufacturers, distributors, and customers.

To make things easier to follow, try using a free graph app. Visualizing your supply chain will help you highlight inefficiencies, bottlenecks, and areas for improvement.

-

Identify bottlenecks and factors influencing costs

Identifying bottlenecks is vital in optimizing your supply chain. Imagine a situation where your business experiences frequent delays in receiving raw materials from a specific supplier.

As a result, you suffer from production slowdowns and increased costs. It is a warning sign of a potential bottleneck.

Applying Lean Six Sigma principles can help businesses systematically identify and eliminate inefficiencies, ensuring smoother operations and cost reductions.

By identifying this, you can explore alternative suppliers or negotiate better delivery terms to alleviate the issue and reduce the associated costs/delays.

-

Forecast demand and align with production and procurement

Accurately forecasting future demand is the best way to adapt your production and procurement processes for a long-term strategy. Historical data advanced forecasting techniques allow you to predict future demand trends effectively.

To go further, leverage purchase order software. It lets you streamline your procurement of materials and consistently deliver the correct quantities on time.

-

Review vendor and partnership performance

Reviewing vendor and partnership performance is crucial to ensuring third parties don’t disappoint you.

Despite this, research by GlobalTranz found that 34 percent of supply chain leaders have not established the necessary partnerships to handle their logistics demands.

Evaluating vendor performance based on criteria such as on-time delivery, quality, and pricing helps identify underperforming suppliers. Similarly, assessing partnership effectiveness, communication, and alignment provides collaborative success.

Companies seeking to streamline their evaluation process turn to the best supplier management software to automate performance tracking and generate comprehensive analytics reports.

When evaluating the effectiveness of your vendors and suppliers, it’s also critical to consider the role of reliable PCB manufacturers in your supply chain. High-quality PCBs are essential for maintaining the integrity of your electronics production, ensuring minimal downtime and enhanced product performance.

Collaborating with dependable PCB partners can significantly streamline procurement, reduce defects, and improve overall supply chain efficiency.

Free to use image sourced from Unsplash

-

Streamline internal and external communication and collaboration

Efficient communication is imperative for seamless information flow between departments, suppliers, and customers. You can leverage external and internal communication tools, such as contact forms and collaboration tools and platforms.

Collecting all of this data will enhance real-time data-sharing capabilities, coordinate activities, and address issues promptly. You can also explore the use of a chat SDK by integrating it into your website to further improve team collaborations and streamline your workflows.

Implementing these changes will minimize errors and delays and improve satisfaction rates. By using a template to track mileage, you can streamline data collection, enhance accuracy, and simplify expense management.

In another nod to efficiency and cost savings, sourcing high-quality resources for your operations, such as low-mileage second-hand cars, can significantly reduce transportation and logistics costs in the long run.

Reliable vehicles ensure products or staff transport without added expenses of frequent maintenance and replacements.

-

Implement inventory control and warehousing techniques

A growing theme within supply chain optimization is the adoption of ‘edge computing’ tech. That is, smart devices that make their own decisions and act autonomously of a centralized control hub.

These devices are increasingly common in warehouse settings. For example, they can take the form of a series of machines and sensors that work together to wrap and pack away parcels for delivery.

A Gartner report predicts that, by 2025, 25 percent of supply chain decisions will be made across intelligent edge ecosystems.

The advantages of this model include instantaneous decision-making, less reliance on constant Wi-Fi connections, and heightened security measures.

Research how you can optimize your warehouses by including these technologies.

For example, you could use real-time data processing to suggest which storage areas are best for housing certain products based on expected collection time and factors such as size and weight.

Automation in logistics, through edge computing and smart warehouses, will transform supply chain efficiency.

-

Leverage technology for real-time visibility and tracking

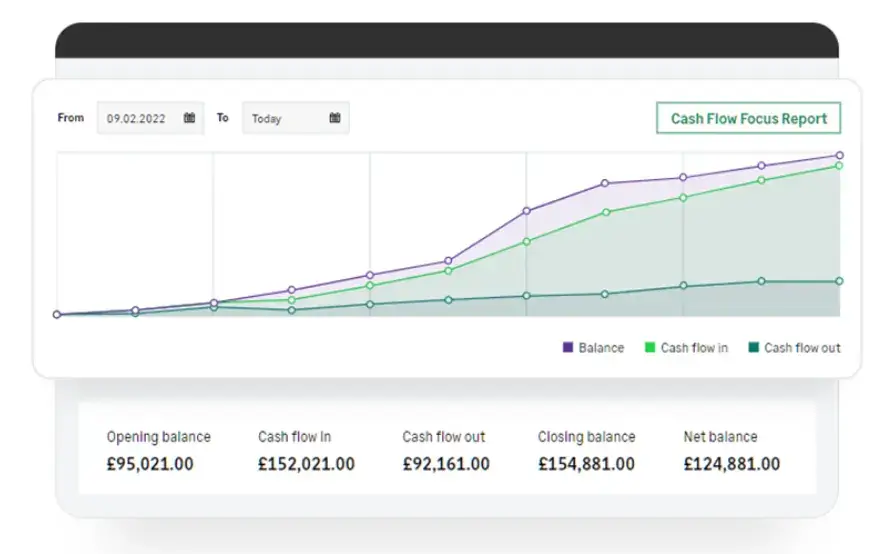

Implementing advanced tracking systems and utilizing accounts payable software are innovative solutions for real-time monitoring of inventory, shipments, and financial transactions.

These tools enhance visibility across the supply chain and allow for proactive decision-making. It will enable you to optimize cash flow management, maintaining efficient operations throughout the supply chain.

Image sourced from Sage.com

-

Optimize logistics and transportation efficiencies

Without logistics and transportation, your supply chains effectively do not exist. So you should constantly review and look for ways to improve these processes.

For example, you could leverage faster delivery with the Upper app to reduce fuel consumption and enhance delivery speed, or utilize technologies such as a 3PL software to streamline warehouse operations, automate order fulfillment, and improve coordination between logistics providers and carriers.

Utilizing transportation software development services can innovate and optimize your logistics operations, ensuring efficient management of routes, schedules, and real-time tracking.

Additionally, collaborate with reliable carriers to provide transparency and tracking features for your warehouses and customers.

-

Monitoring and consistently improving supply chain performance

Monitoring supply chain performance is essential for continuous improvement.

By tracking key performance indicators (KPIs), analyzing data, and conducting regular performance evaluations, you can identify areas for enhancement.

From here, you can put targeted strategies, refine your processes, and proactively address issues.

Make Your Supply Chain Unbreakable with Effective Optimization

Logistics are the backbone of your company’s process. Without them, everything else falls apart.

So, your main priority is to forge a resilient network of suppliers and distributors and plan for expected demand/sales. Doing so will lead to increased profitability, agility, and market advantage.