As eCommerce continues to grow, the importance of a streamlined logistics process grows as well.

Incorrect shipments and delays are more than logistical problems — they are threats to customer satisfaction and business credibility.

Fortunately, we’ve researched and developed six strategies to help you avoid incorrect shipments and delays in your logistics process.

In this article:

- Implement Address Verification Software

- Manage All Processes with Logistics Software

- Use Barcode Scanners

- Conduct Regular Inventory Audits

- Diversify Your Carrier Portfolio

- Maintain Open Communication with Carriers

According to a study by Convey, Inc., 98% of consumers say shipping impacts brand loyalty, and 84% are unlikely to return after a single negative delivery experience.

Source: Convey

1. Implement Address Verification Software

A recent Loqate report found that incorrect or incomplete addresses cause 41% of delivery delays and 39% of delivery failures.

Address verification software validates and corrects shipping addresses in real time. This reduces returns, prevents delivery mistakes, and ensures packages arrive at the correct destination on the first attempt.

Source: Loqate

Beyond reducing delivery errors, address verification software enhances customer satisfaction, lowers return costs, and streamlines your logistics workflow.

2. Manage All Processes with Logistics Software

Tracking your logistics process is essential for minimizing errors and ensuring timely deliveries. Here are key software tools that help:

Order management software

Order management software (OMS) centralizes order activity and provides visibility from order entry to fulfillment.

Key features include:

- Order Fulfillment Automation: Reduces human error and speeds up picking, packing, and shipping.

- Real-Time Tracking: Allows proactive management of potential delays.

- Inventory Tracking: Helps maintain accurate stock levels.

- Order Analytics: Identifies bottlenecks and trends.

- Refund/Exchange Management: Streamlines returns to avoid further errors.

- Customer Data Management: Ensures shipping accuracy and enhances personalization.

Fleet management software

Fleet management software helps optimize the physical transport of goods with features like:

- Real-Time Vehicle Tracking: Quickly identify and resolve delays.

- Route Optimization: Uses real-time road data to select the fastest path.

- Automated Dispatching: Ensures the right vehicle goes to the right location.

- Maintenance Alerts: Prevent breakdowns and unexpected delays.

- Integrated Driver Communication: Reduces miscommunication and speeds issue resolution.

- Fleet Card Integration: Allows companies to manage and monitor fuel purchases, spending limits, and driver transactions in real time.

Supply chain visibility platforms

These platforms offer:

- Real-Time Tracking: Live updates on shipment locations and status.

- Automated Alerts: Instant notifications when issues arise.

- Inventory Visibility: Ensures accurate stock levels across locations.

- Carrier Performance Analytics: Helps you choose the most reliable shipping partners.

- Demand Forecasting: Improves planning accuracy and avoids shortages or overstock.

Tip: Opt for AI-based logistics software

Using logistics solutions enhanced with AI—such as those that support predictive analytics and smart alerts—creates a more efficient and adaptive supply chain.

AI-driven systems deliver faster decisions, fewer errors, and more intelligent logistics management.

3. Use Barcode Scanners

Barcode scanners ensure the correct items are picked for each order, reducing incorrect shipments and fulfillment mistakes.

When integrated with your OMS, scanners:

- Update inventory automatically

- Reduce manual entry errors

- Speed up processing times

This simple tool significantly improves accuracy and efficiency throughout the logistics workflow.

4. Conduct Regular Inventory Audits

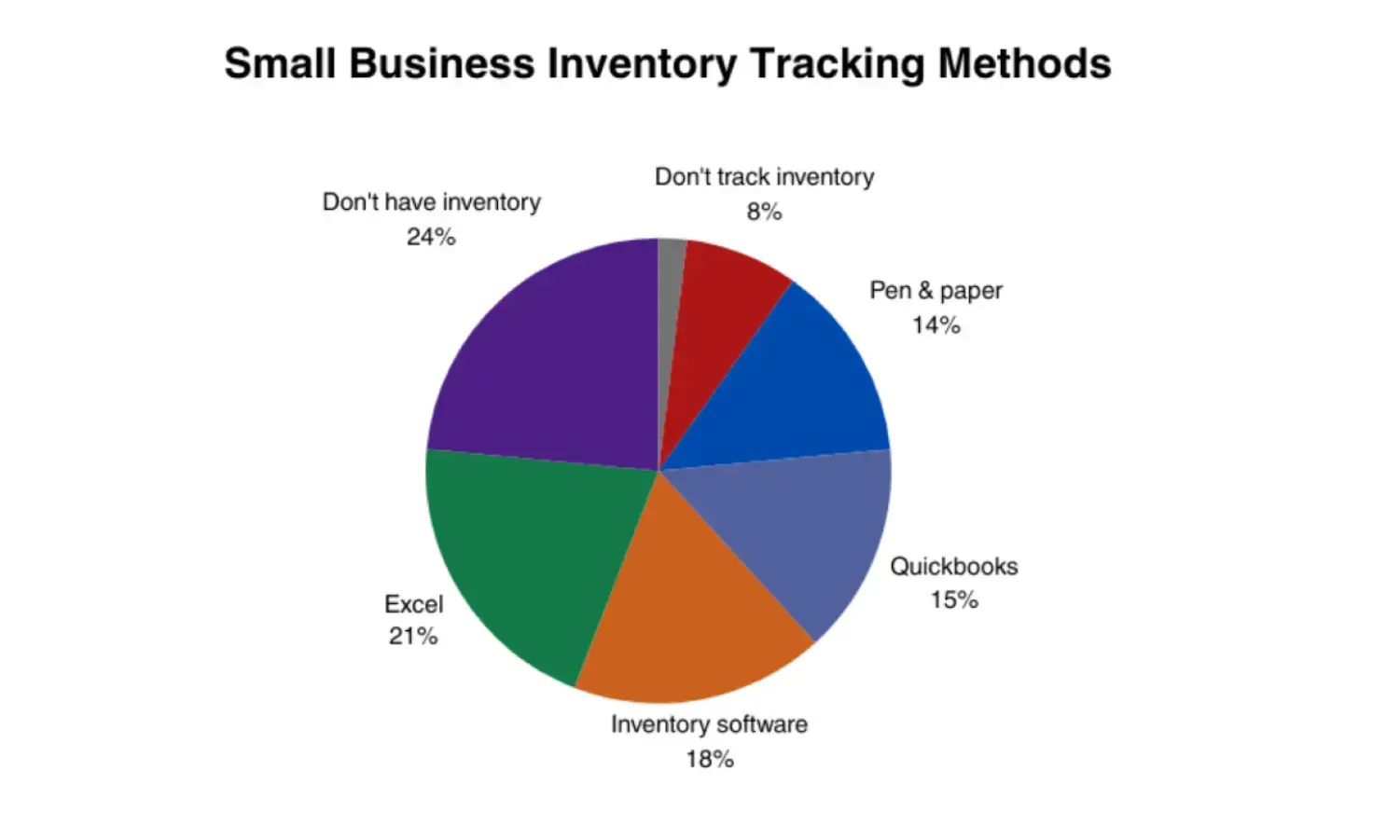

According to supply chain statistics, 43% of small businesses use outdated inventory tracking methods.

Source: Wasp Barcode

Outdated systems often create:

- Stockouts

- Overstocking

- Misplaced inventory

- Incorrectly picked items

Regular audits reveal inventory discrepancies and improve overall accuracy.

They also support better inventory management, reducing stockouts and improving customer satisfaction.

Common types of inventory audits include physical counts, cutoff analysis, freight cost analysis, overhead checks, and reconciliation.

5. Diversify Your Carrier Portfolio

Relying on one carrier puts your logistics pipeline at risk. Issues like labor strikes, weather disruptions, or peak season backlogs can derail your entire delivery schedule.

Using multiple carriers gives you flexibility and reliability when unexpected delays arise.

Tip: Use a shipping aggregator

Aggregators provide access to multiple reputable carriers and help you select the best option for each shipment based on speed, cost, and reliability.

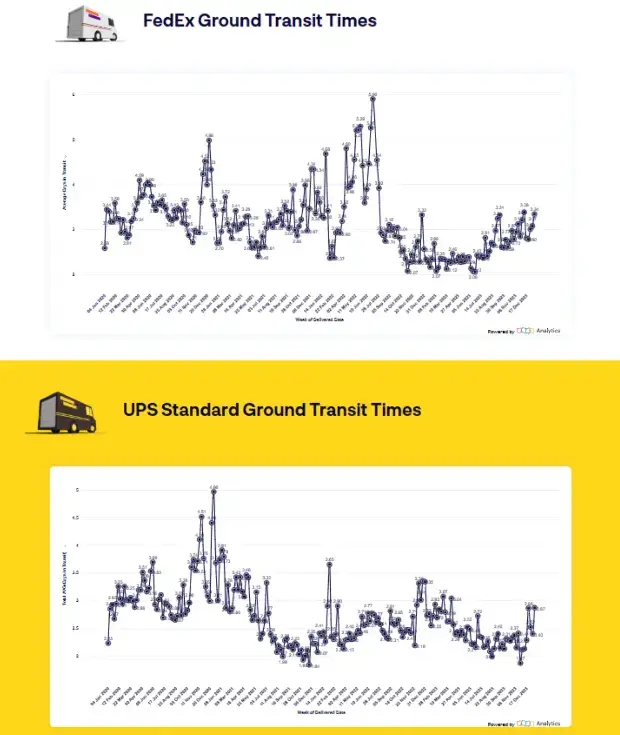

Tip: Monitor carrier transit times

Regularly analyze time-in-transit data from your carriers—such as those listed by eShipper—to refine your shipping strategy.

Source: ShipBob

A proactive approach helps you:

- Provide accurate delivery estimates

- Avoid preventable delays

- Choose optimal carriers for each region

6. Maintain Open Communication with Carriers

Strong carrier relationships lead to better communication and faster problem resolution.

Benefits include:

- Quick adaptation to shipping issues

- Faster dispute or delay resolutions

- More accurate and timely customer updates

Good communication improves transparency and strengthens trust with both carriers and customers.

Conclusion

Every step you take toward refining your logistics process strengthens your brand reputation, improves customer trust, and supports long-term growth.

Apply these strategies and build a seamless, reliable, and error-free logistics system that powers your business forward.

Author Bio

Alexandra Kalasky is an experienced logistics professional passionate about optimizing supply chain processes. Her work provides actionable insights and innovative solutions designed to enhance operational efficiency.