Imagine a scenario where you have been talking to a customer who wants a high-value item. You overcome all their objections, and the customer agrees to the sale. However, they need it the next day.

When you check your stock levels, you are horrified to find that it’s out of stock and will not be available for a few days. Disappointed, the customer goes to one of your competitors.

Skip to:

- How Do You Work Out How Much Safety Stock to Carry?

- What is Safety Stock’s Importance to Your Business?

While that is an imagined scenario, the reality is that out-of-stock and overstock costs North American retailers a staggering $349 billion every year.

How can you avoid scenarios like this and the associated losses? The simple answer is safety stock. What is safety stock, and how can you use it to ensure you don’t lose sales or customers?

What is Safety Stock?

Just as you might have torches and/or candles in case of a power cut, safety stock is your emergency backup for your products.

Safety stock is excess products you keep in hand in case there is a rush on those products or if you encounter any problems with logistics and your supply chain.

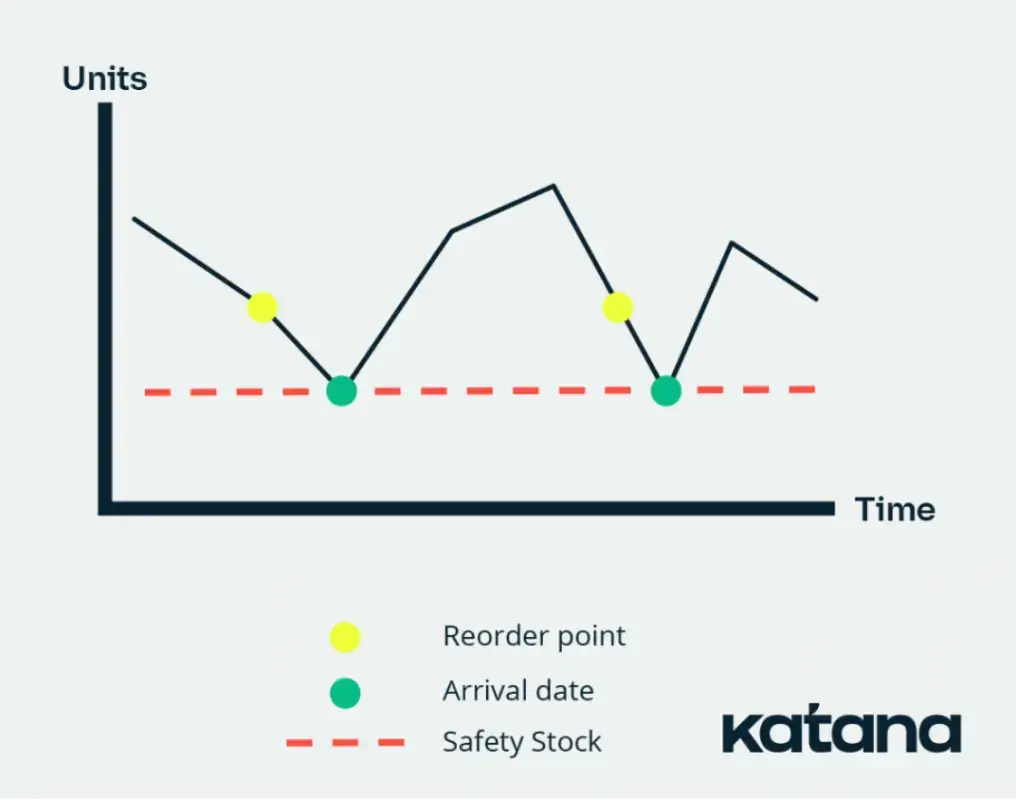

You likely use demand forecasting to estimate how much a product will sell in a given period. Those predictions inform you about ordering (and reordering) stock and inventory management.

However, although demand forecasting can be an important part of business management, it doesn’t allow for the unexpected. Let’s go back to imagined scenarios.

You are due for delivery on Thursday, but extreme weather conditions, which we seem to have more and more of, means that your normal logistics provider can’t deliver to your fulfillment center for several days.

Luckily, you adopted a safety stock strategy the year before and have enough of a ‘cushion’ to see you through until the delivery is made.

How Do You Work Out How Much Safety Stock to Carry?

If you run an ecommerce business and carry thousands of products, having safety stock for every SKU (stock-keeping unit) you have may not be feasible.

Just like demand forecasting, it’s a case of identifying patterns. Which SKUs have a high turnover and may run out in case of an emergency or a sudden rush on that product?

You may be using an inventory management solution that can help you identify popular products and calculate the amount of safety stock you should consider.

If not, the formula to work that out is surprisingly easy and can be done in four steps.

Demand forecasting is essential for identifying popular products, especially when dealing with indirect procurement and managing non-core items.

1. Figures

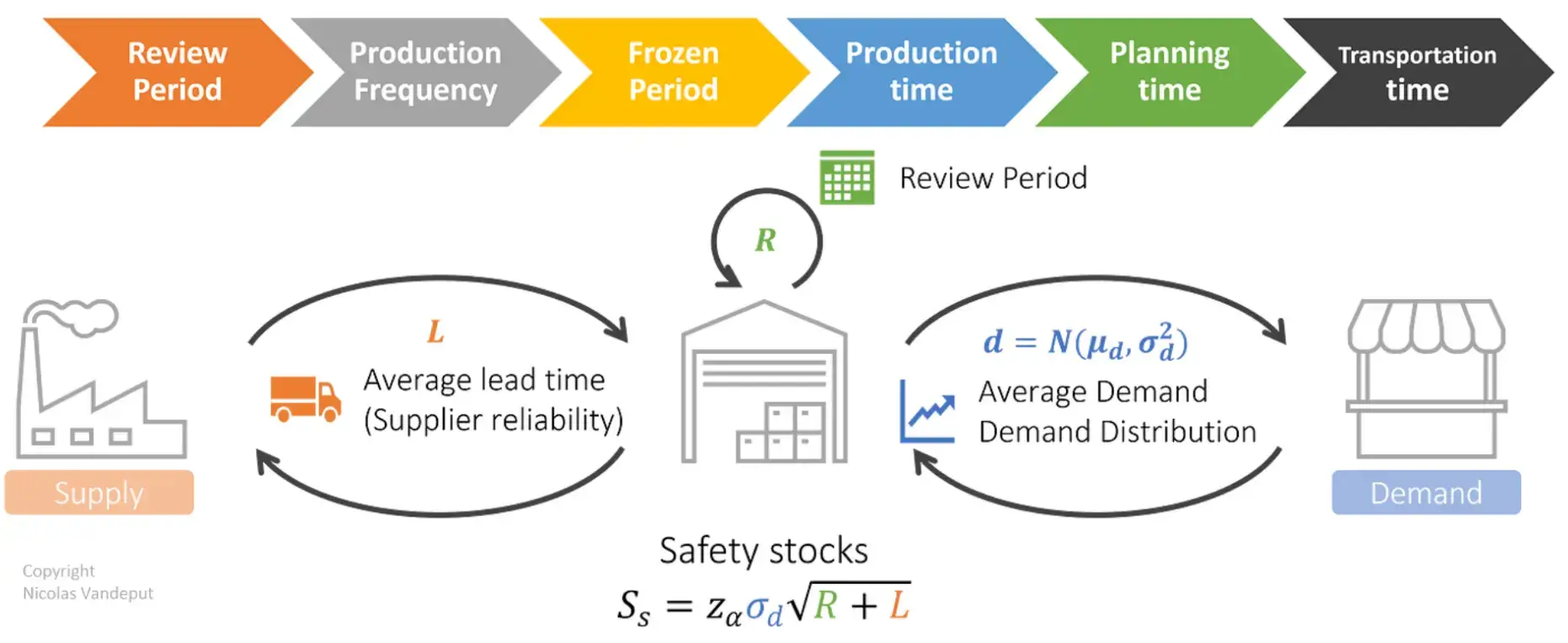

As with any mathematical formula, you will need some figures to work with. When it comes to safety stock, there are four you need:

- Maximum daily usage. This is the highest volume of an SKU you have sold in a specific period. That could be an actual day or a week or could even refer to a season.

- Maximum lead time. What’s the longest your supplier (or logistics provider) takes to deliver that SKU to your premises or fulfillment center? This is from the point you make an order or when automatic reordering happens.

- Average daily usage. What are your average sales of that SKU over a certain period? This can be somewhere that seasonal fluctuation can affect figures. To further modernize your safety stock and logistic strategies, consider incorporating AI-based solutions that optimize both demand forecasting and inventory management processes. Implementing these approaches can help minimize risks related to unexpected demand fluctuations or supply chain disruptions. Companies are increasingly turning to AI consulting for logistics to gain insights into more efficient and scalable supply chain practices. After all, you would sell more Xmas trees in the run-up to Xmas than you would the rest of the year.

- Average lead time. What’s the average time taken for product delivery? This will differ from the maximum lead time, as that can be affected by different factors.

It is important to note that there is no ‘one size fits all.’ Different types of retailers will have vastly different demands regarding inventory and inventory management.

A supermarket is totally different from an omnichannel contact center that sells a range of audio and video equipment.

2. Maximums

Now, you need a maximum figure. You get this by multiplying your maximum daily usage by your maximum lead time.

These are your worst-case scenario figures, representing what would happen if you sold the most SKUs you could and your supplier or logistics provider took the longest possible time to restock you.

For example, if the most you had ever sold of a particular product was 17 units in a day and the longest delivery was 8 days, you’d multiply the two and get 136. In some cases, you might also want to think about where people are in your leads and sales funnels and when they might make a decision.

3. Averages

As with your maximums, this is a straightforward multiplication. Take your two average figures to give a single average for the formula.

If you sold an average of 12 of that SKU and your deliveries took an average of four days, then your overall average figure (for the purposes of calculating safety stock) would be 48.

4. Calculate your safety stock needs

Whether you sell D2C (direct to consumer) or have a B2B and enterprise sales cycle model, the fact is that you can’t always be sure what might happen.

As the saying goes, expect the unexpected, or at least be prepared for it.

So, now you’ve whittled the four figures you started with down to two so that you have an idea of the safety stock you need. To get this, subtract your average figure from your maximum figure.

In the examples given, that would be 48 subtracted from 136, giving you 88. In this case, the safety stock you would need is 88 SKUs of that product.

What is Safety Stock’s Importance to Your Business?

Every business wants to avoid lost sales.

And it’s not only sales; if you are out of stock on an item, the disappointed customer might find that product elsewhere and decide to go with the business that met their needs in the future.

You need to understand the different benefits that having a safety stock strategy will bring you.

1. Fewer stockouts

It may not be possible to completely avoid stockouts, especially if you have a large product range and limited warehouse space.

You can analyze your data, recognize patterns, and try to avoid stockouts on popular items.

You may have policies in place that trigger reordering when stock runs low, but safety stock is about protecting you from unexpected events. It’s all about providing optimum customer experiences (CX), and just as aligning your sales and support teams can help in one area of CX, safety stock can help in another.

2. Optimizing warehouse use

Warehousing isn’t free. Depending on your business size and location(s), you may utilize more than one warehouse.

Your inventory management system can track different figures from multiple locations, and you also need to consider whether any costs would negate the usefulness of safety stock.

But in most cases, that safety stock can be very useful, especially given the growth of ecommerce.

Safety stock strategies can effectively protect your business, but optimizing your infrastructure—like utilizing custom mezzanines—can further help improve efficiency.

Facilities often face the challenge of how to best optimize space and store adequate excess products.

Custom mezzanines provide an innovative solution that maximizes vertical space without expanding existing footprints, ensuring inventory management becomes streamlined while also preventing stockouts.

Explore how implementing such infrastructural changes can support supply resilience.

3. Forecasting demand

Demand forecasting can be quite closely tied to safety stock calculations. Over time, you can compare data on both to see how accurate your predictions were. This allows you to make adjustments based on your forecast versus what happened.

4. Recognizing the seasonal needs

Seasonal patterns can be very different from the rest of the year.

You may also have periods when you offer discounts on products, and both should be taken into account when calculating safety stock.

For example, you may plan a July sale, during which you will offer 50% off products that help businesses work within the COSO framework. Anticipating a rush means you can plan a larger safety stock than normal.

5. Efficiency

Having some safety stock of your popular items can mean your business operates more efficiently. You avoid stockout scenarios and can fulfill any orders that come in while you are awaiting a restock of those items.

6. Happy customers

Stockouts can mean unhappy customers, and that’s something you want to avoid.

Generally, customers don’t know - or care - about any issues they might face, such as supply chain disruption. They just want to order an item successfully. In some cases, such as during a legacy modernization process, they might even need that item urgently.

Customer satisfaction will always be important, and having safety stock is one factor that can contribute to that.

The Takeaway

Free to use image sourced from Pixabay

Many factors can influence your decisions on safety stock.

While the obvious ones are how many SKUs of a product you sell and how long it takes to replenish that stock, you also need to think about things such as warehousing costs.

In some cases, such as with supermarkets, you also need to consider whether a temporary stockout will really cause issues. Perhaps the biggest risk that causes stockouts is supply chain problems.

Depending on how your supplier or logistics provider operates, these can range from adverse weather conditions to mechanical issues with the vehicle being used to deliver to you.

A safety stock strategy can reduce risk and work in parallel with demand forecasting.